Refining clay into gold, this "Su made" craft almost lost, what kind of story is hidden behind it

Text/Ying Zhigang

One year, I was particularly obsessed with old bricks because after carving them, they could be used to plant calamus or used for artistic daily play.

My friend in Suzhou learned and gave me a piece of A4 sized leftover brick as a gift. And it is declared that it is a "golden brick" obtained from the "imperial kiln".

At that time, I didn't pay attention and made a sample on the brick, just took a knife to carve it. The carving knife, which usually carves bricks like mud chips, unexpectedly destroyed two of them, leaving only a few shallow marks on the bricks.

After working in Suzhou, I had a serious encounter with the "Golden Brick" and went to interview and report on the completion of the Imperial Kiln Golden Brick Museum as a media outlet.

The BRICS Museum is now a national 4A level scenic spot, located on Yangcheng Lake West Road in Xiangcheng District. Walking on the road, the storefront may not be big, but there is a vast universe inside.

The main building combines the style of ancient kilns and palaces, so the front hall of the museum is very tall and majestic, expressing an abstract visual of a palace.

The BRICS Museum blends elements of classical Jiangnan gardens from the entrance to the main building, using a long corridor to follow the layout technique of "changing scenery and winding paths".

But around the main body, there is more of a "broad and desolate" atmosphere, and a large number of plants with a sense of desolation such as reeds and dogtail grass are selected around the exhibition hall.

Walking through the long corridor, my eyes suddenly opened up. An abstract palace stood on the desolate land, invisibly adding the weight and vicissitudes of history.

According to historical records, Yuyao Village, where the museum is located, has been producing gold bricks since ancient times. During the prosperous Qing Dynasty, 72 households and 78 kiln sites were designated as "official kilns" for the imperial palace to produce gold bricks.

There are three ways to describe the name of BRICS. Firstly, the gold bricks have a tight texture and produce a metallic sound when struck; Secondly, in ancient times, the gold bricks fired in official kilns were exclusively used for the imperial palace, and because they were laid on the ground of the Golden Luang Hall, they were considered precious.

The last version is that the gold bricks were transported from Suzhou to the capital city by canal, and when spread out, the transportation cost of each brick exceeded one or two pieces of gold, hence the name gold bricks.

According to official historical records, the bricks used for laying the ground are made of "earth" and "gold", and their properties of "harmony between water and fire, and long-lasting quality" imply the eternal stability and longevity of the country. Therefore, since the Ming Dynasty, they have been referred to as "golden bricks" in folk and court archives; During the Kangxi reign of the Qing Dynasty, all inscriptions, administrative documents, and imperial edicts officially referred to "gold bricks".

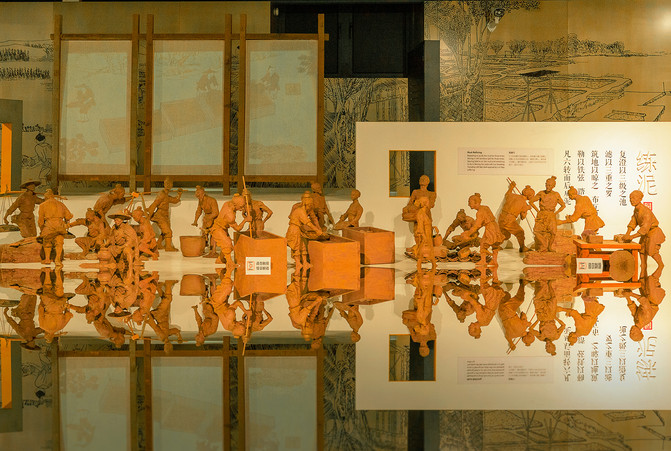

The ancient firing process of gold bricks is extremely complex, with as many as 29 production steps. It revolves around the 24 solar terms of the year, and involves taking soil, refining mud, making bricks, drying in the shade, loading the kiln, firing the kiln, soaking water, and exiting the kiln according to the weather. The intricate and tedious processes make the final formation of a gold brick almost exhaust the energy and effort of the kiln workers for a year.

In the museum, there is an unburned brick slab that was carved with a sharp blade, leaving only a shallow mark. Just bricks are as hard as rocks, let alone bricks?

It is said that the clay used for gold bricks is not immediately usable. It needs to be washed several times with water alone, and then filtered through a fine sieve after settling. The formation of a pile of clay requires about three months of six processes: clarification, filtration, drying, kneading, and stepping.

Apart from the complexity in the early stage, firing bricks after they are formed is not a one-time process. First, use firewood, straw, rice husks, and other materials as fuel. Let it burn on low heat for over a month, then use chopped wood for over a month, and finally use pine branches for 40 days. During the 5-month firing process, people must control the kiln temperature step by step to prevent the fire from being too intense and causing the bricks to crack, and not let the temperature inside the kiln be too low or the smoking time be insufficient to produce yellow "tender fire bricks".

After firing, it is necessary to soak the water, usually using 4800 pounds of water for 300 pounds of bricks and tiles. Continuously releasing water from the sealed kiln roof, slowly seeping into the kiln seat. When the water encounters high temperatures, it turns into steam, which is compatible with the fire god inside the kiln, causing the bricks to undergo kiln changes from reddish brown to bluish black.

A gold brick is a microcosm of how the people of Suzhou conform to the Tao of Heaven.

When to take soil, when to practice clay, when to dry in the shade, when to fire, all must follow the changes of the solar terms, otherwise the same process and the same soil cannot be refined into gold bricks in the Golden Luang Hall.

Due to the exquisite craftsmanship of making gold bricks, in ancient times, gold bricks could only be luxury items made for the royal family as ordered.

Until the fall of the Qing Dynasty, gold bricks were no longer just used as flooring materials. Literati and literati use it as an elegant cultural display, which can be used to study calligraphy on bricks, as a chessboard, or made into various craft ornaments, giving new life to gold bricks.

Previous Article:These ancient styles are full of travel experiences, coupled with Hanfu, be careful when wearing them in time and space! The more!

Next Article:Humble Administrator's Garden, Mother of Gardens in the World (Part 2)-Suzhou 2 (3)